Your Position: Home - Plastic Products - PET Protective Film FAQ

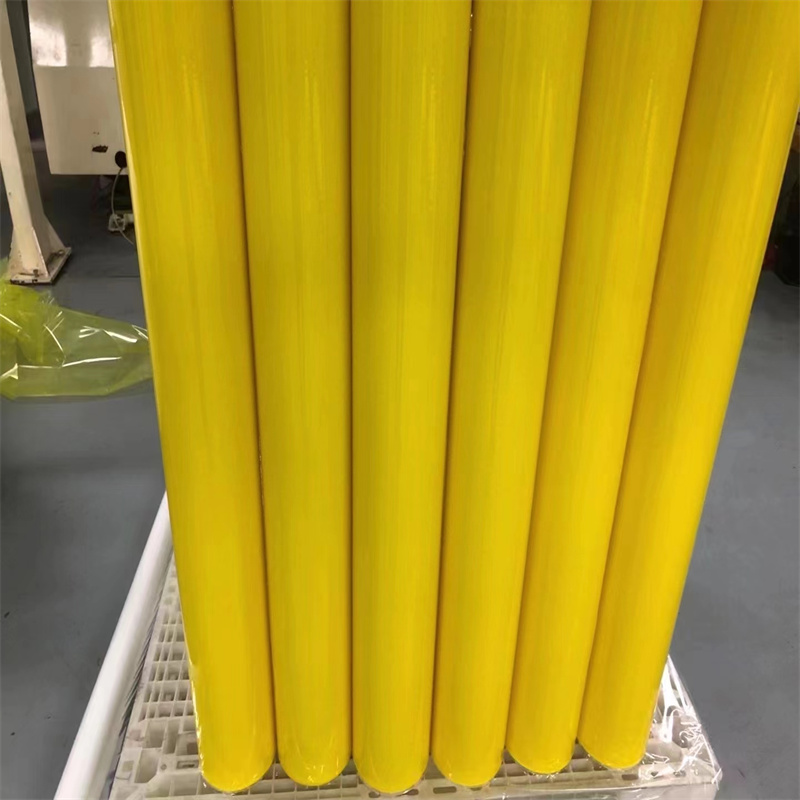

PET protective film is known for its relatively hard texture and is a common choice for surface protection across various products. These include metal items, coated metal products, plastic goods, automotive components, and digital devices.

The primary role of PET protective film is to safeguard product surfaces from scratches and corrosion during production and transport. Unlike PVC protective film, PET film does not turn yellow or oily and can be recycled.

In this article, we address the common issues encountered with PET protective film.

When removing the protective film, the adhesive usually stays attached to the film. However, sometimes the adhesive remains on the product's surface. Degumming is a frequent issue when PET protective film is applied to profiles.

The most common reason for PET high-temperature resistant protective films degumming is inadequate lamination. For example, if the glue's viscosity is too high, it becomes difficult to detach the PET film from the product.

Dealing with degumming can be troublesome. To address this, use a clean cloth dipped in a small amount of alcohol and wipe the affected area repeatedly. Be careful not to damage the product's surface finish during this process.

Peeling off the PET protective film during transportation and use is a common issue. This can be considered from two angles:

The molding machine's pressure during the upper mold is insufficient.

The product's surface is unclean, with dust or other foreign objects affecting the bonding.

Additional reading:If the pressure is insufficient, test and increase the film's pressure. If foreign matter is present, clean the surface with a cloth dipped in a small amount of alcohol. After applying the film, check for air bubbles between the film and the product.

Two scenarios make the PET protective film hard to peel off: difficulty in tearing off and breaking during peeling.

If the film is hard to remove, the adhesive might be too sticky. Use a special photosensitive adhesive designed for protective films.

If the film breaks during peeling, the material used in the PET film might not withstand the peeling force. This is troublesome for users and hard to manage. Refer to the degumming solution for cleaning.

Sometimes, the corners of the PET protective film wrinkle after a period of use. This may be due to excessive stretching force during the application process, causing unwanted shrinkage.

Though PET film has strong weather resistance, environmental temperature differences can affect it. Excessive force during application can overstretch the surface.

Many problems with PET protective film arise from quality issues. Purchasers should learn to identify and choose high-quality PET protective films to ensure product quality.

The article emphasizes the importance of addressing common issues with PET protective films, such as degumming, poor adhesion, difficulty in peeling off, and corner wrinkling. By understanding these problems and their solutions, users can better protect their products and maintain their quality. For more details please contact PET Protective Film Supplier

Additional reading:296

0

0

Comments

All Comments (0)

Related Articles

Top Benefits of R1/1SN Hose Service You Need Today

In the world of hydraulic systems, hoses play a pivotal role in ensuring seamless operation and efficiency.

By Grace

157

0

0

10m Polyester Mesh Cloth vs. Traditional Fabrics: Which is Better?

With increasing options for fabrics, many wonder if 10m polyester mesh cloth can outperform traditional fabrics in terms of versatility and performance.

By May

118

0

0

How to Choose OEM Four Wire Spiral Hydraulic Hose?

# How to Choose OEM Four Wire Spiral Hydraulic Hose?

By Elva

114

0

0

How to Choose Polyester Filter Belts?

Choosing the right polyester filter belts for your industrial needs can be a daunting task, especially given the variety of options available in the market.

By Vic

161

0

0

Sanyeflex vs. Competitors: Which Option Best Suits You?

When it comes to choosing the right product for your needs, the comparison between Sanyeflex and its competitors can be pivotal.

By Harry

144

0

0

How Spiral Mesh Belts Transform Petrochemical Processes?

Understanding Spiral Mesh Belts Spiral mesh belts significantly enhance petrochemical processes by improving efficiency and ensuring uniform heat distribution.

By Evelyn w

133

0

0

Is Your Polyester Filter Screen Reducing Efficiency Over Time?

Understanding Polyester Filter ScreensPolyester filter screens are widely used in various industries for their excellent filtration properties.

By Melody Liu

120

0

0

How Does a Continuous Belt Filter Work Efficiently?

In the evolving realm of industrial filtration, the continuous belt filter stands out as a remarkable innovation, offering efficiency and reliability that meet the demands of various applications.

By Joy

94

0

0