Your Position: Home - Minerals & Metallurgy - How galvanized steel coils are made

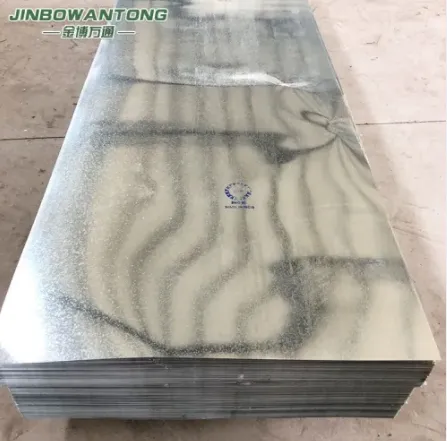

Galvanized steel coil is a type of steel product that has undergone a galvanization process, where a protective layer of zinc is applied to the steel to prevent corrosion. The process of making galvanized steel coil involves several steps:

Material Selection:

The process starts with the selection of high-quality steel coils. These coils can be made from various grades of steel, and their composition depends on the intended use of the galvanized steel.

Cleaning and Pickling:

The steel coils are cleaned to remove any oil, grease, or other contaminants on the surface. This is typically done through a series of alkaline and acidic cleaning solutions in a process known as pickling.

Fluxing:

After cleaning, the steel coils are fluxed to facilitate the bonding of the zinc coating. Fluxing involves applying a special flux solution to the steel surface, which helps in the galvanizing reaction.

Galvanizing Bath:

The cleaned and fluxed steel coils are then immersed in a bath of molten zinc at temperatures typically ranging from 815°F to 850°F (435°C to 455°C). This bath contains a mix of zinc and other metallurgical additives.

Galvanizing Reaction:

In the galvanizing bath, a metallurgical reaction occurs between the zinc and the steel. The zinc coating bonds to the steel through a process called hot-dip galvanizing. This forms a protective layer of zinc-iron alloy over the steel surface.

Quenching:

After the galvanizing process, the steel is rapidly cooled or quenched to solidify the zinc coating. This step is crucial to ensure the formation of a durable and adherent zinc layer on the steel.

Skin Pass Rolling:

The galvanized steel coil may undergo a process called skin pass rolling, where it is subjected to a light rolling to improve the surface finish and enhance flatness.

Inspection and Quality Control:

The galvanized steel coil undergoes thorough inspection to ensure that the coating is uniform, adherent, and free from defects. Quality control measures are taken to meet industry standards and customer specifications.

Coil Packaging:

Once the galvanized steel coil passes inspection, it is coiled and packaged for shipment. The coils are often tightly wound and secured with strapping to ensure safe transportation to end-users or downstream manufacturing facilities.

Advantages of Galvanized Steel Coil:

Corrosion Resistance: The zinc coating provides excellent corrosion resistance, protecting the steel from rust and other forms of degradation.

Durability: Galvanized steel is known for its durability and long lifespan, making it suitable for various applications in construction, automotive, and manufacturing.

Versatility: Galvanized steel coils are used in a wide range of applications, including roofing, siding, automotive parts, HVAC systems, and more.

Cost-Effective: The initial investment in galvanized steel is often offset by its long-term durability and low maintenance requirements.

Galvanized steel coils are widely used in construction and manufacturing due to their protective coating and robust properties, making them a popular choice for a variety of applications.

Get access to Galvanized Steel Coil suppliers

408

0

0

Comments

All Comments (0)